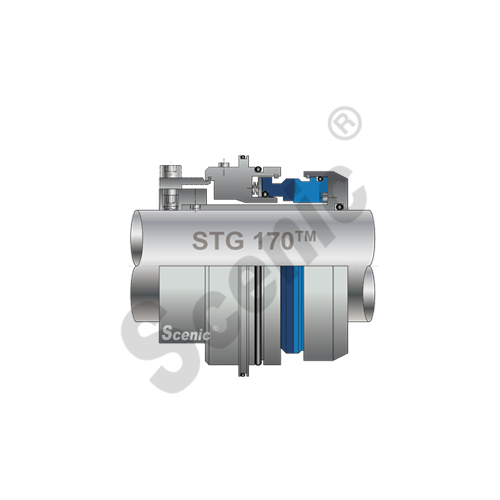

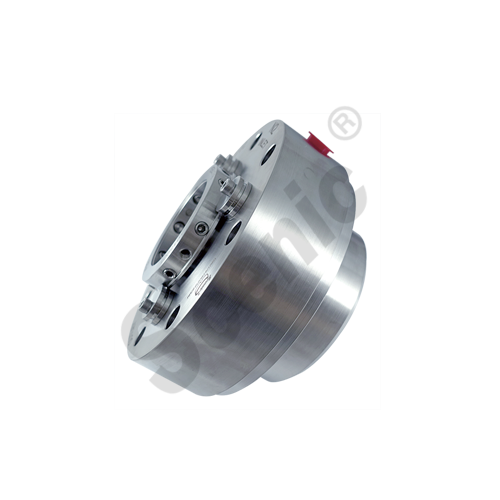

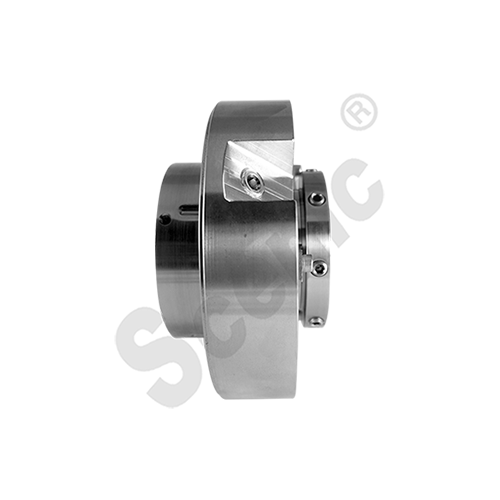

Steam Turbines Gas Seal STG170

PATENTED

☑ Patented Inflective Grooves

☑ For Steam Turbines

☑ Reduced Energy / Load / Heat / Vibration

☑ No Auxiliary System Required

☑ Low Maintenance Cost

☑ Patented Inflective Grooves

☑ For Steam Turbines

☑ Reduced Energy / Load / Heat / Vibration

☑ No Auxiliary System Required

☑ Low Maintenance Cost

Model :

STG170

Specifically designed for steam turbines.

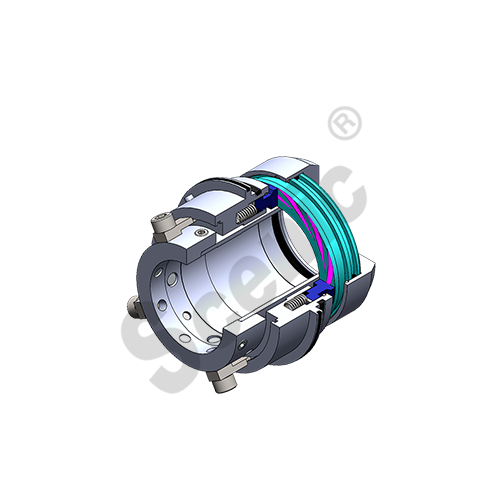

- High reliability with non-contact shaft seal exhibits near zero wear.

- Utilizes the steam from the turbine as a power source for the dynamic interposed gas film in the sealing surface.

【Operating Capabilities】

- Temperature: -20 ~ 280℃ (-4 ~ 536 ℉ )

- Pressure: 0 ~ 14 kg/cm2G

-

Surface Speed: 600 ~ 1,000 fpm

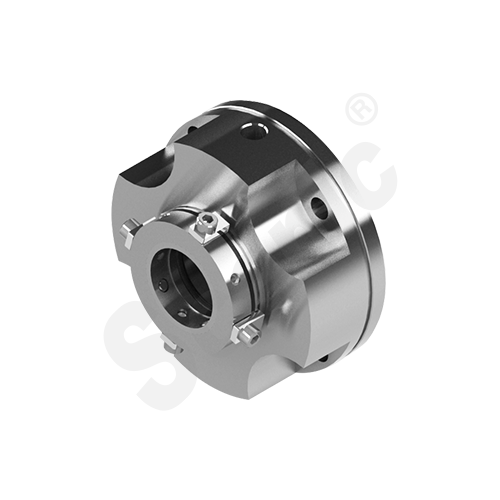

- Stationary Ring:Metal Carbon

- Rotary Ring:Hard Carbide

- Metal Parts:Titanium / Duplex / Inconel / CAP42

- Elastomeric O-rings:FFKM / SceniRAZ / Graphite

- Springs:Special Metal

- No contact of seal faces. In normal operation, seal faces separate and generate a sealing gap preventing friction and wear which prolong seal duration.

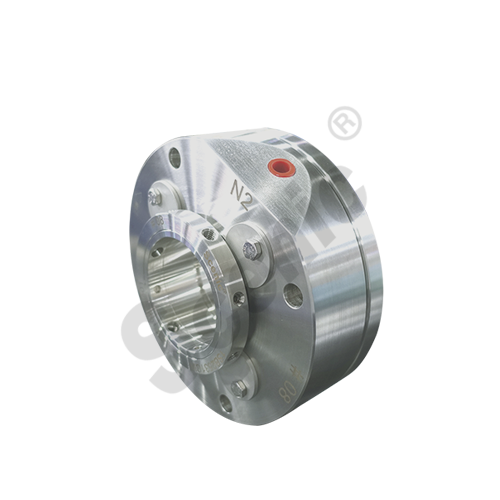

- Low power consumption due to non-contacting faces. Seal faces generate significantly less heat and torque, and will not affect turbine's stability.

- Self steam lubricated. Reacts sponteneously to maintain normal sealing gap.

- Eco-friendly & Low Maintenance Cost. Near-zero vapor leakage, eliminates carbon rings usage and cost-down maintenance.

- Durable & reliable, relieved of turbine's bearing & oil steam contamination, maintaned clear & clean operating space.