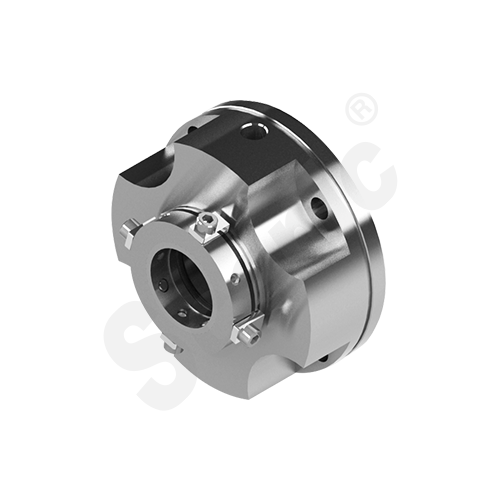

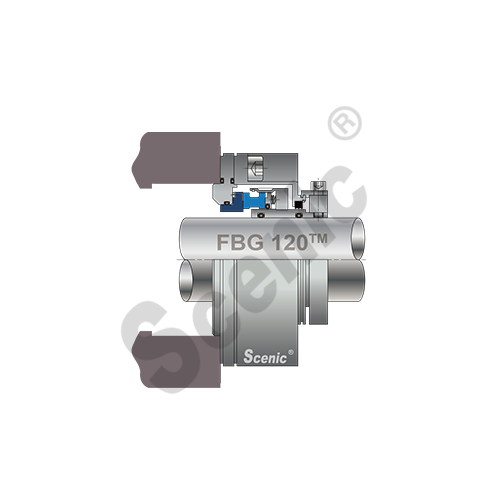

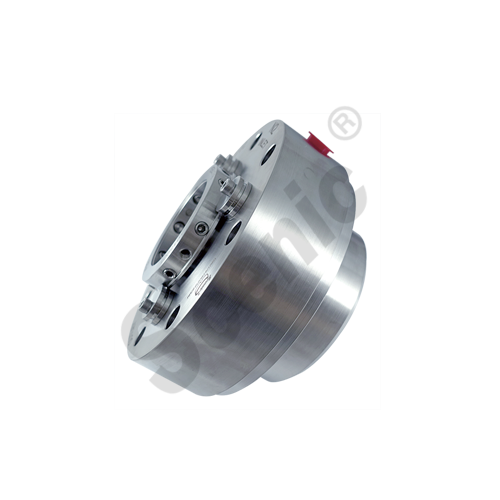

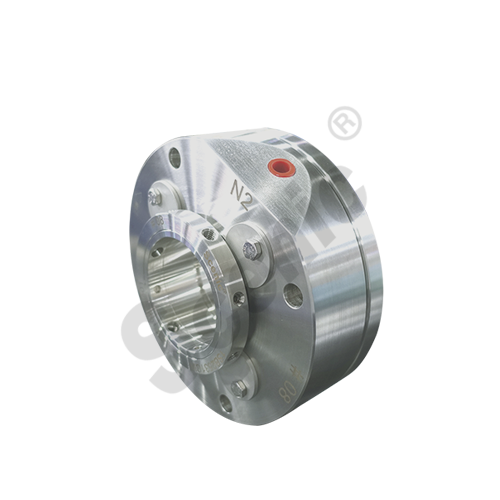

Non-Contact Single Gas Seal FBG120

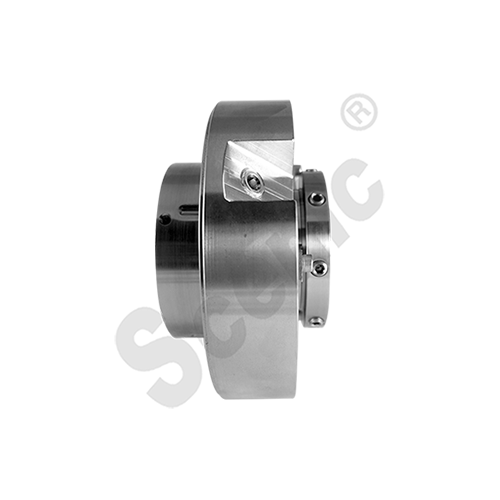

☑ External Cartridge Seal

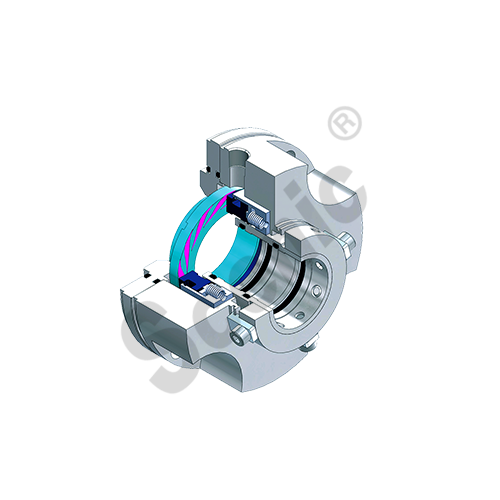

☑ Patented Inflective Grooves

☑ No GSP Required

Dry gas seals are used to prevent gas leaks in a variety of industrial applications, especially in centrifugal compressors, pumps and other rotating equipment. Unlike traditional liquid seals, dry gas seals operate without any liquid lubrication.

The FBG®120 utilizes patented inflective grooves technology, which generates hydrodynamic force during operation, causing the face to separate from the seat and creating a rigid gas film for effective sealing. Additionally, this technology significantly reduces friction and wear, thereby enhancing sealing efficiency and lifespan.

As an externally-installed single gas seal, it can utilize atmospheric air to create a dynamic lifting gas film under low pressure or zero pressure, requiring no external source of gas or support system accessories. The cartridge-type design facilitates easy installation and reduces maintenance costs, while ensuring safety, reliability, and an eco-friendly sealing solution.

※ More Customized Sealing Solution. Please feel free to contact us.

Catalog Download

Catalog Download

【Operating Capabilities】

- Temperature: -20 ~ 230 ℃ (-40 ~ 446 ℉)

- Pressure: 0~0.5 kg/cm2G

-

Surface Speed:600~1000 fpm

- Stationary Ring:Silicon Carbide / Tungsten Carbide

- Rotary Ring:Carbon Graphite

- Metal Parts:SUS304 / SUS316 / SUS316L / 316Ti / Hastelloy C / Titanium / Duplex / Monel®

- Elastomeric O-rings:FFKM : Chemraz® / Kalrez® / SceniRAZ® ; Viton / NBR / Aflas(HTCR) / EPDM / PFT / Hiflour

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:SUS316 / Hastelloy C / Inconel®

- Convenient to assemble, disassemble, and install.

- Seal uses spiral groove technology to create a gas film principle between the seal faces. During operation, the inert gas penetrates throught the spiral grooves to generate a lift, and establish a sealing gap.

- Non-contacting Seal Faces. Required power consumption is just 5%~12% in compararison to wet seal. Minimized wearable materials, support equipments and maintence costs.

- Below normal pressure, utilized rotation speed in influenzing atomospheric pressure as inert gas to establish sealing gap.

- Non-complicated assesory system, convinient to restore, highly dependable.

- In normal operation, dry gas seal may continously run for years without the need to stop for maintenace.

- Designed for various rotating equipment, such as pumps, steam turbines, mixers, agitators, blowers, windmills, & other rotating equipment.