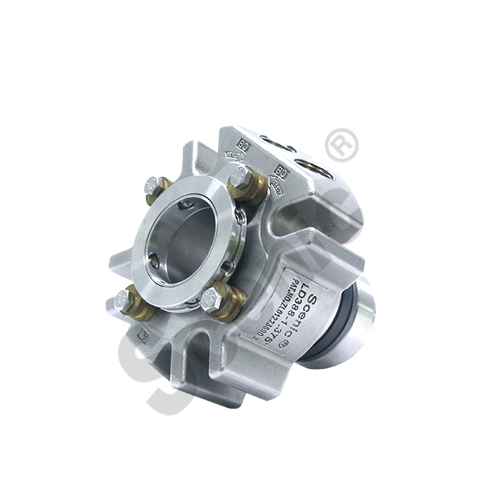

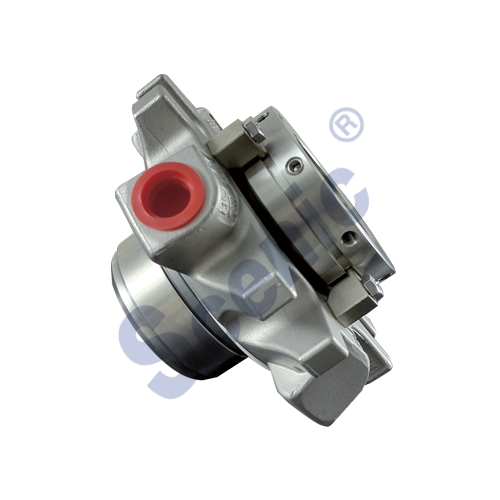

Dual Mechanical Seal LD388 / LD389

PATENTED

☑ Dual Cartridge Seal

☑ Restrains VOC Emission

☑ Standard DIN/ANSI

☑ High temp.

☑ High Pressure

☑ Isolated Springs

☑ Dual Cartridge Seal

☑ Restrains VOC Emission

☑ Standard DIN/ANSI

☑ High temp.

☑ High Pressure

☑ Isolated Springs

Model :

LD388 / LD389

Conforming to DIN/ANSI standards, this preassembled and preset cartridge seal is compact and ready-to-fit, thereby speeding installation and maintenance, and eliminating setting errors.

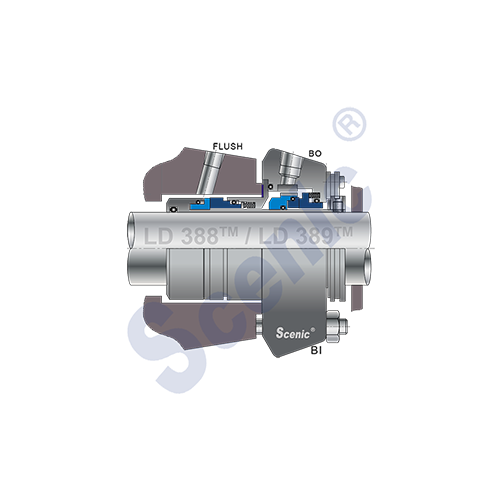

With an SP-3GL seal reservoir installed, the seal can restrains/eliminate/minimize VOC emissions to comply with the environmental emission regulations, leading to improved air quality during a manufacturing process.

In addition, this seal features balanced design for both pressure directions; it can be used with a pressurized barrier fluid or unpressurized buffer fluid, and thus is extremely successful in realizing nearzero emissions. The proven high performance of the seal ensures that customers have the right seal for their needs.

With an SP-3GL seal reservoir installed, the seal can restrains/eliminate/minimize VOC emissions to comply with the environmental emission regulations, leading to improved air quality during a manufacturing process.

In addition, this seal features balanced design for both pressure directions; it can be used with a pressurized barrier fluid or unpressurized buffer fluid, and thus is extremely successful in realizing nearzero emissions. The proven high performance of the seal ensures that customers have the right seal for their needs.

※ More Customized Sealing Solution. Please feel free to contact us.

Catalog Download

Catalog Download

【Operating Capabilities】

- Temperature: -40 ~ 230°C (-40 ~ 446 °F )

- Pressure: Up to 355.6 psig (25 kg/cm2G)

-

Surface Speed: Up to 5000 fpm (25 m/s)

【Standard Materials】

- Stationary Ring:Silicon Carbide / Tungsten Carbide

- Rotary Ring:Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZTM / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

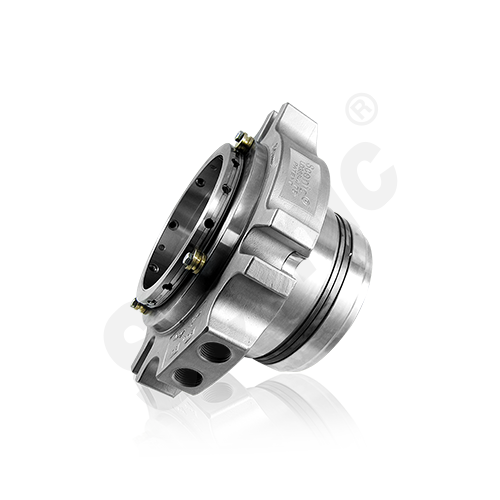

- Advanced cartridge-mounted transmission system: With drop-proof springs, the seal can readily be installed or replaced (applicable only to the LD388 series, which is compatible with big and taper bore pumps)

- High duty transmission mechanism: The transmission components can tolerate large shaft runout (radial movement) and vibration that occur predominantly during startup and shutdown.

- Non-clogging stationary springs: Providing an evenly distributed load on the sealing faces, our enhanced springs are mounted in the stationary section of the seal and completely isolated from the process medium during operation, therefore free from stress corrosion and damage caused by a crystallizing or clogging medium with solid particles, such as dirt and debris.

- Robust pressure-transmission compression rings: The proven cartridge design features rugged compact construction and long sealing face life, resulting in less downtime and extended MTBF(Mean Time Between Failures).

- High efficiency induced heat pumping: With the assistance of the rotating pumping ring, which is located directly under the venting outlet hole in the gland ring, in circulating the cooling fluid, this design provides the best possible cooling fluid supply to carry away seal-generated heat and thus the best cooling effect at the sealing faces.

- Self-aligning: Allows for shaft runout up to ±0.8 mm, increasing operational reliability.

- Solid one-piece sealing rings: Produced with high quality and accuracy, the API 682 compliant sealing rings are resistant to wear and deformation, ensuring high integrity sealing performance.

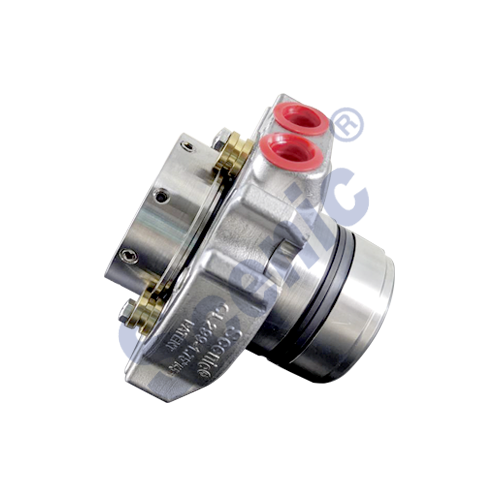

- Anti-collision washers: An added safety feature to avoid metal-to-metal collision sparks by using an impact absorbing washer eliminates the possibility of on-site catastrophic fire, promoting high safety in operation.

- Micro-polished outer surfaces of the sealing rings for anti-stick mounting: The seal outer surfaces on which the O-rings are mounted have been fine finished so that the O-rings can slide axially along the rotating shaft, avoiding hang-up problems with the dynamic O-rings.

- The LD389 series is designed to have a shorter seal chamber than that of the LD388 series so that it can share spares with the CarLife family seals.

- Suitable for rotating equipment in compliance with DIN / ANSI standards and big bore / taper bore dimensions, such as chemical processing pumps, vertical pumps and large industrial pumps.

- Compatible with API 682 piping plans 52/53/54, this seal works well with a barrier / buffer fluid pressurized or unpressurized, depending on the application requirements.

- Designed for rotating equipment that needs resistance to the adverse effects of acidic, caustic, corrosive, volatile and toxic media, and requires a dual seal to prevent VOC emissions.

- Widely used in the alcohol (e.g. methanol and ethanol), biodiesel and corn processing industries.

- Ideal for a wide variety of industrial applications, including food and beverage, pharmaceutical, petroleum, petrochemical, chemical, pipeline transportation, steel, semiconductor and power generation.