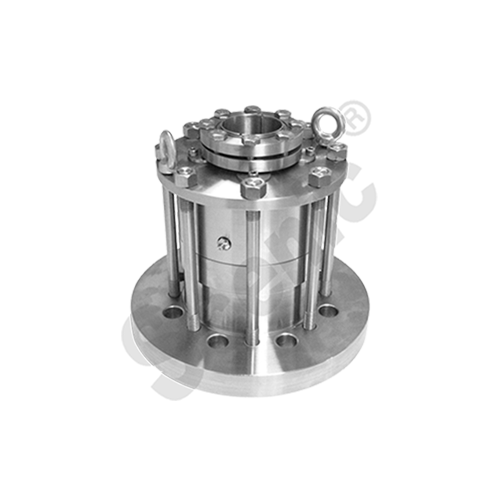

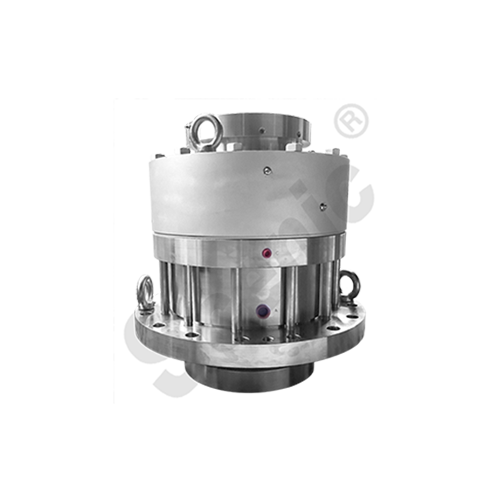

Gas Seal for Mixer & Agitator GSB300

PATENTED

☑ Non-contacting Sealing Faces

☑ Inflective Grooves Technology

☑ Mixers / Reactors / Fermentation Tank

☑ Absolute Zero Emission

☑ Clean Processes

☑ Non-contacting Sealing Faces

☑ Inflective Grooves Technology

☑ Mixers / Reactors / Fermentation Tank

☑ Absolute Zero Emission

☑ Clean Processes

Model :

GSB300

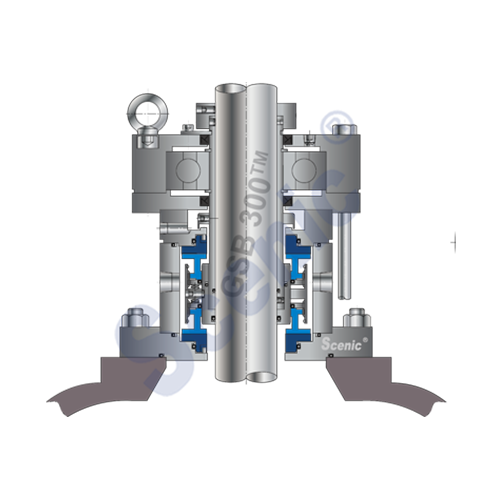

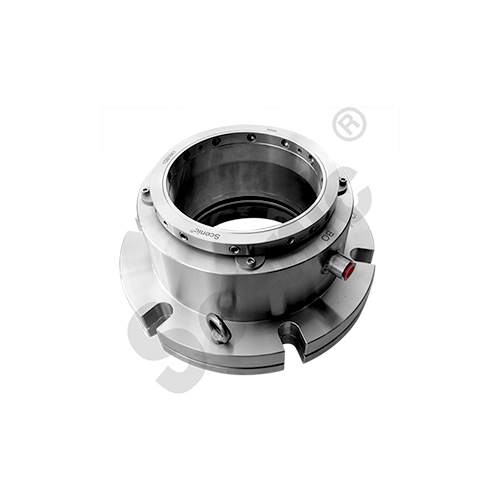

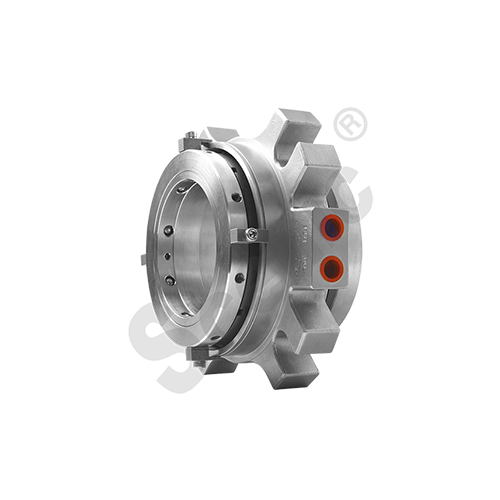

Introducing the GSB300 mechanical seal, a game-changer for mixers and agitators with its non-contact cartridge design. Engineered to optimize efficiency, it minimizes heat generation and power consumption, thanks to its non-contacting sealing mechanism.

Featuring Inflective Grooves Technology, the GSB300 prevents fluid contamination and eliminates the need for a wet support system, ensuring a clean and efficient operation. It's the go-to solution for sealing volatile elements in petrochemical and chemical processes, offering unparalleled reliability.

Featuring Inflective Grooves Technology, the GSB300 prevents fluid contamination and eliminates the need for a wet support system, ensuring a clean and efficient operation. It's the go-to solution for sealing volatile elements in petrochemical and chemical processes, offering unparalleled reliability.

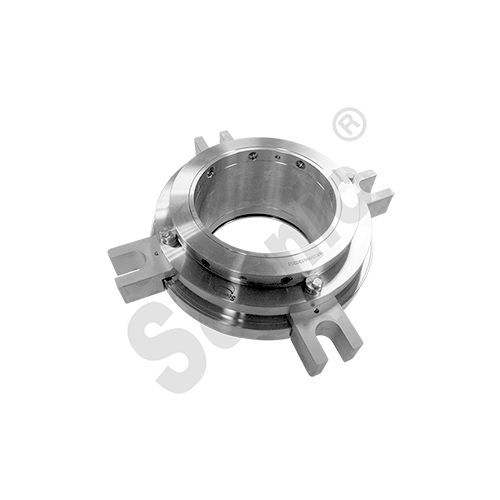

【Operating Capabilities】

- Temperature: -40 ~ 150°C (-40 ~ 300 °F )

- Pressure: Up to 142 psig (10 kg/cm2G)

-

Surface Speed: Up to 984 fpm (5 m/s)

【Standard Materials】

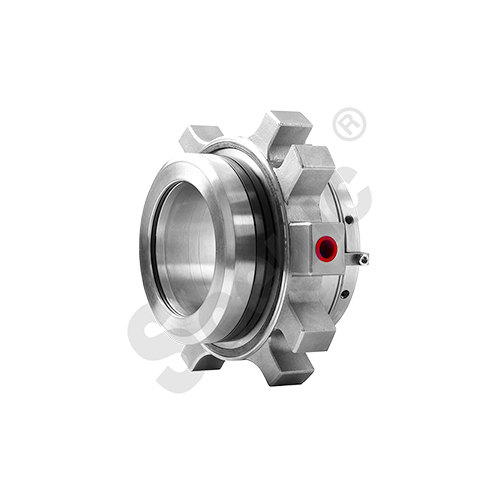

- Stationary Ring:Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZ® / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

- Applying Plan 74 with only N2 auxiliary system, and without a cooling system. Achieving a clean operating condition and environment.

- In coordination with the N2 auxiliary system, a stable and clean gas source can be maintained to achieve zero VOC leakage.

- No discarded lubricating oil or cooling fluid. Reduced consumption of oil & water resources. Observed co-existence with the environment.

- Non-contacting seal faces, minimized wearable materials, support equipment and maintenance costs.

- Reduced cost, power and vibration due to the non-contacting seal faces. Required power consumption is just 5%~12% in comparison to wet seal.

- The patented cartridge design features innovative drop-proof springs, thereby speeding installation and maintenance.

- Uncontaminated springs, less stress, no corrosion or hang-up condition.

- High-purity, clean and pollution-free processes, such as pharmaceuticals, fermentation, chemistry, electronics, etc.

- Process substances compatible with nitrogen.

- Impurity-free, volatile and dry fluid process.

- Stirring equipment with high and low speed, low and medium pressure.

- Double-sealed rotating equipment with VOC volatilization control requirements.