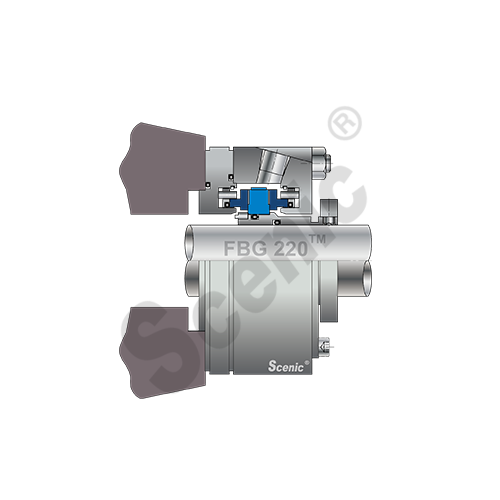

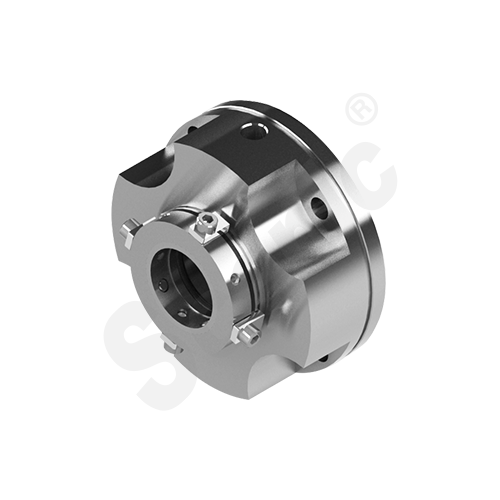

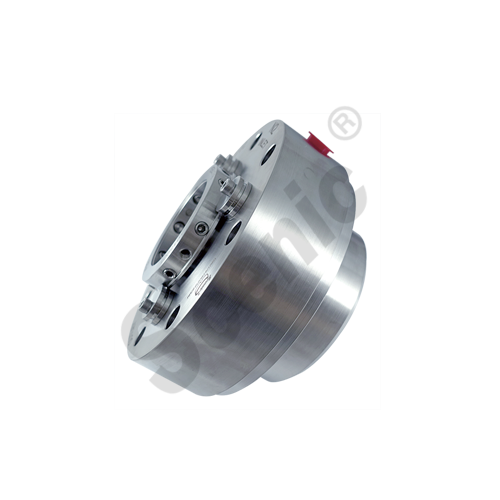

Non-Contact Dual Gas Seal FBG220

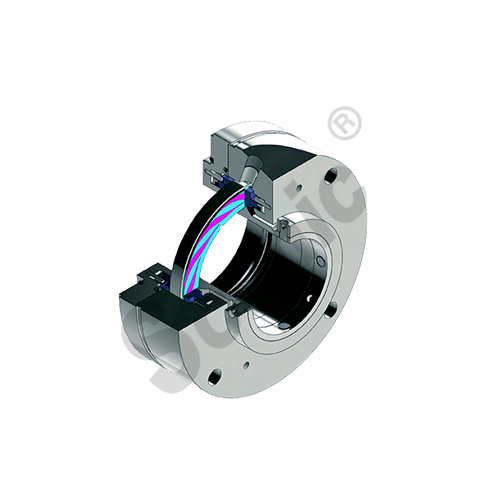

☑ Patented Inflectional Grooves

☑ Face-to-Face Arrangement

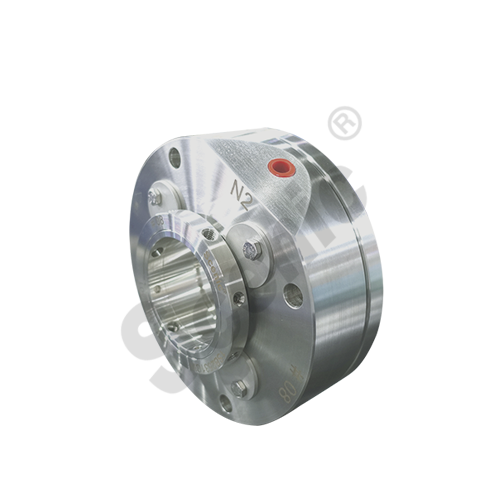

☑ API Plan 74 With GSP

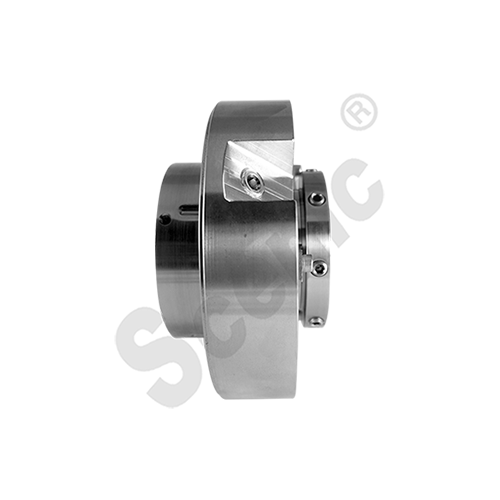

Dry gas seals are used to prevent gas leaks in a variety of industrial applications, especially in centrifugal compressors, pumps and other rotating equipment. Unlike traditional liquid seals, dry gas seals operate without any liquid lubrication.

The FBG®220 utilizes patented inflective grooves technology, which generates hydrodynamic force during operation, causing the face to separate from the seat and creating a rigid gas film for effective sealing. Additionally, this technology significantly reduces friction and wear, thereby enhancing sealing efficiency and lifespan.

This face-to-face arrangement gas seal features a shared rotating ring, making it exceptionally lightweight. Its integral sealing ring resists deformation, providing superior precision and wear resistance. Utilizing Plan 74 with N2 or a gas support system eliminates the need for cooling water or other accessories, ensuring a clean working environment with zero VOC emissions. The cartridge-type design facilitates easy installation and reduces maintenance costs, while guaranteeing safety, reliability, and an eco-friendly sealing solution.

※ More Customized Sealing Solution. Please feel free to contact us.

Catalog Download

Catalog Download

- Temperature: -20 ~ 230°C (-40 ~ 446 °F )

- Pressure: Vacuum to 200 psig (14 kg/cm2G)

- Surface Speed: 600 ~ 6000 fpm

-

Poping Plans:PLAN 74 with Gas Support System

- Stationary Ring:Metal Carbon

- Rotary Ring:Hard Carbide

- Metal Parts:SUS304 / SUS316 / SUS316L / 316Ti / Hastelloy C / Titanium / Duplex / Monel

- Elastomeric O-rings:FFKM : Chemraz® / Kalrez® / SceniRAZTM ; Viton / NBR / Aflas(HTCR) / EPDM / PFT / Hiflour

- Springs:Special Metal

- Minimal power consumption. Diminished costs & energy requirements of accessories related with lubricating and cooling systems.

- Low power consumption due to non-contacting faces. Seal faces generate significantly less heat and torque, and will not affect turbine's stability.

- Face to face seal arrangement. Unwetted springs. Stress & corrosion free. Eliminated matters crystalizing effect and impurities clogging effect problems.

- Merely N2 as system source. Cooling system not required. Achieved clean operating condition and environment.

- Less power requirement. Power consumption of gas seal is just 5%~12% in comparison to traditional wet seal; conserves significant amount of wearable materials and support systems.

- Fitted with N2 control panel. Must maintain stable clean nitrogen. Attained VOC zero leakage.

- No discarded lubricating oil or cooling fluid. Reduced consumption of oil & water resources. Observed co-existence with the environment.

- Designed for various rotating equipment, such as pumps, steam turbines, mixers, agitators, blowers, windmills, etc.