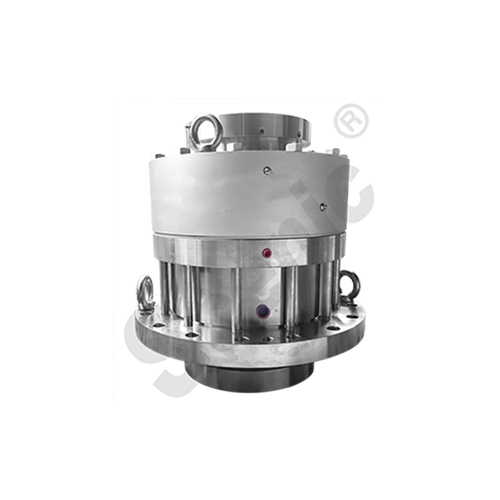

Dual Mixer Cartridge Seal MGSRDB

PATENTED

☑ Back-to-Back

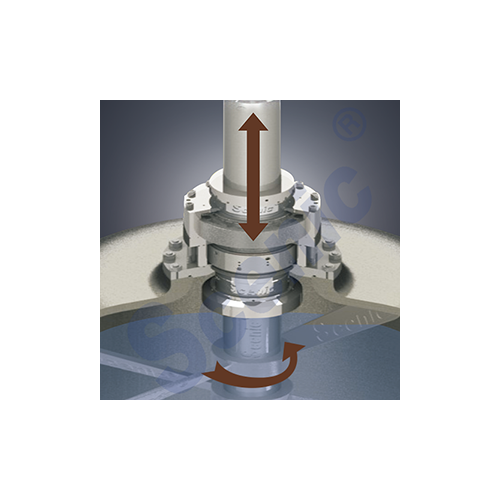

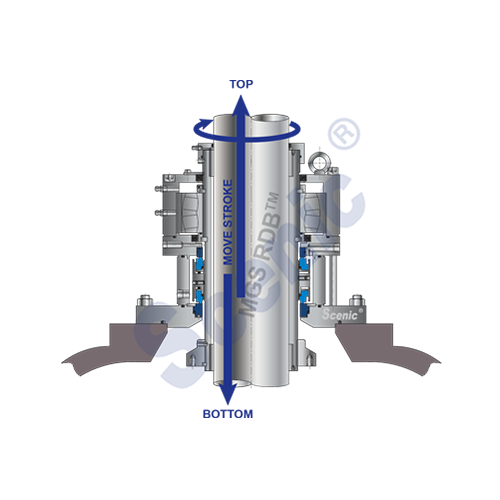

☑ For Mixers with Reciprocating Shaft

☑ Back-to-Back

☑ For Mixers with Reciprocating Shaft

Model :

MGSRDB

MGSRDB effortlessly accommodates axial expansion and radial rotation of the shaft while maintaining unwavering sealing integrity.

Designed for versatility, the MGSRDB excels in a multitude of applications, particularly in the fine chemical and pharmaceutical industries.

Its advanced capabilities enable uniform mixing and low-temperature drying concurrently, making it an ideal solution for processes sensitive to heat and viscosity variations. Experience unparalleled efficiency with the MGSRDB as its unique stirring method ensures swifter and more uniform mixing, significantly reducing processing time.

Designed for versatility, the MGSRDB excels in a multitude of applications, particularly in the fine chemical and pharmaceutical industries.

Its advanced capabilities enable uniform mixing and low-temperature drying concurrently, making it an ideal solution for processes sensitive to heat and viscosity variations. Experience unparalleled efficiency with the MGSRDB as its unique stirring method ensures swifter and more uniform mixing, significantly reducing processing time.

【Operating Capabilities】

- Temperature: MGS-D / MGS-DB -40 ~ 150°C (-40 ~ 300 °F )

- Pressure: Up to 350 psig (35 kg/cm2G)

-

Surface Speed: Up to 4920 fpm (25 m/s)

- Stationary Ring:Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZ® / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

- Huge Mixer/Agitator/Vessel.

- Rotating equipments with big shaft run-out or high speed at high temperature.

- Dual sealing required to prevent VOC emission for rotating equipment.

- Pulp and paper, petrochemical, foodstuff processing, chemical processing, pharmaceutical, power generation.

- Applied in handling high viscosity, and easy to crystallization fluids.

- Scenic® enables to supply special design in accordance with customer requirement.