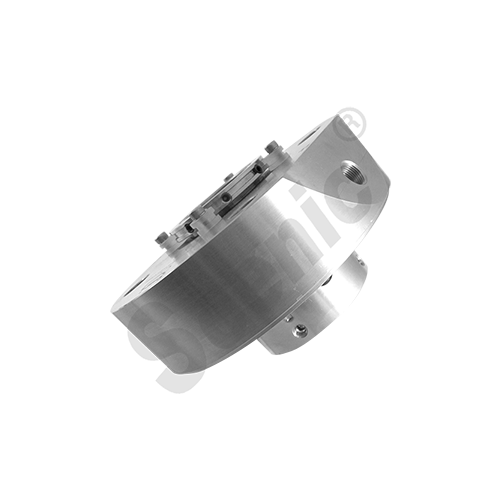

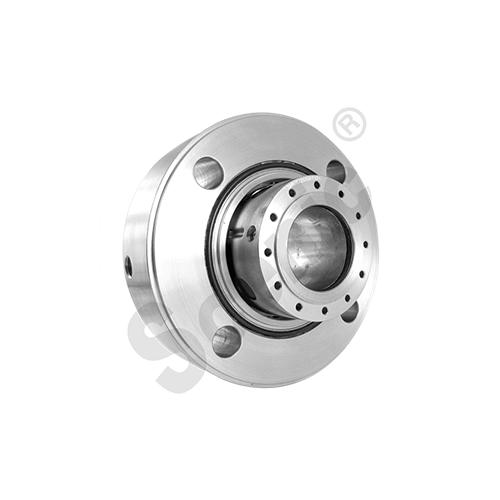

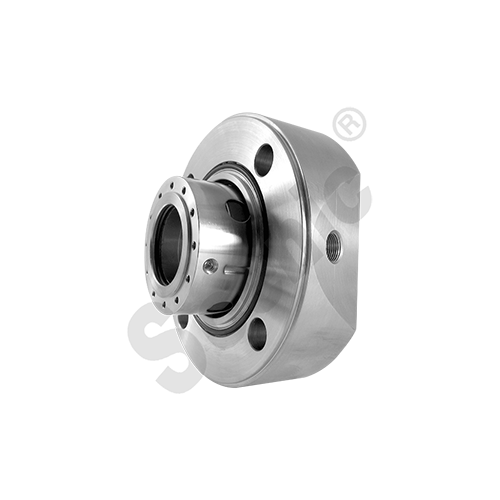

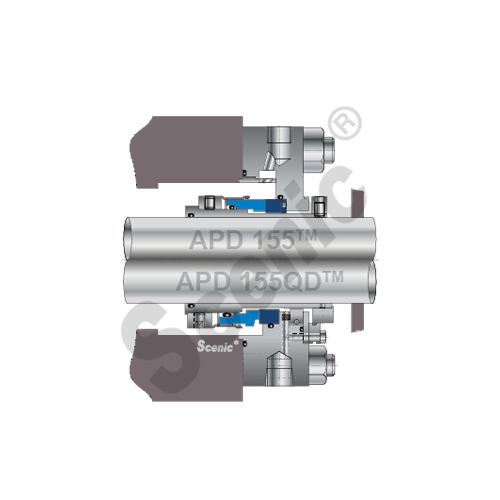

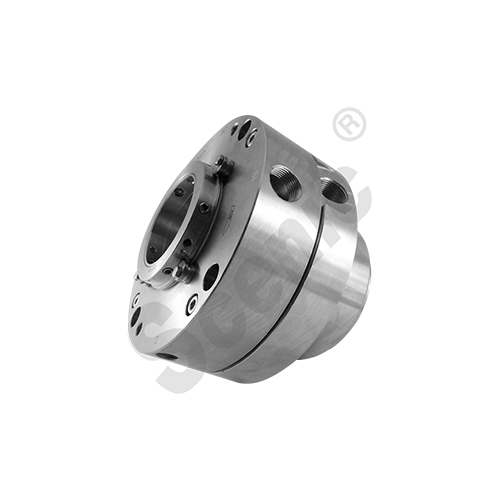

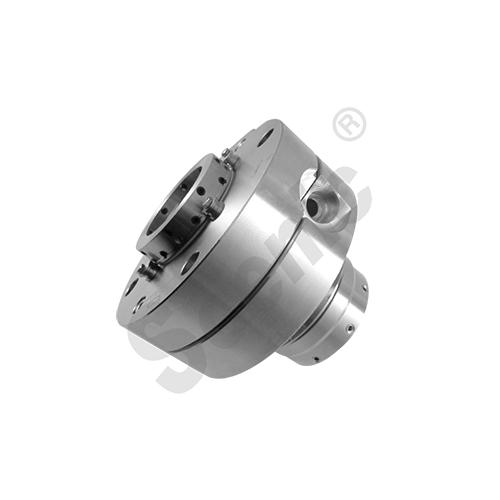

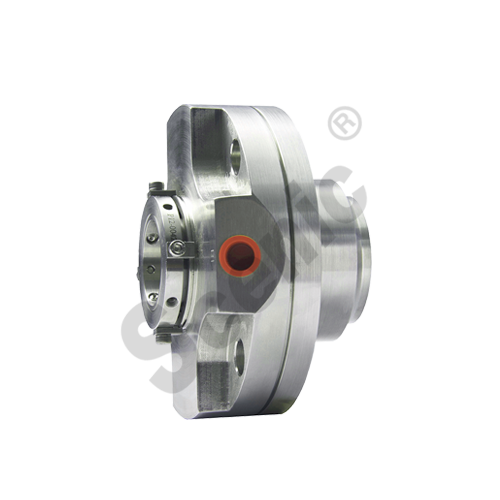

Single Cartridge Seal APD155/APD155QD

PATENTED

☑ Single Cartridge Seal

☑ API 682 Standard

☑ High temp.

☑ High Pressure

☑ Single Cartridge Seal

☑ API 682 Standard

☑ High temp.

☑ High Pressure

Model :

APD155/APD155QD

For refining, petrochemical and geothermal energy industrial applications

The APD®155/APD®155QD seals are designed, manufactured, and tested in full compliance with the revised API 682 4th Edition. With rugged compact construction, the APD®155 series is ideally suited for high-temperature and high-pressure applications, as well as fluid transportation processes that have no VOC issues.

Specially designed to cover the needs of the refining, petrochemical and renewable energy industries, this seal delivers reliable performance and long life across many applications when used in conjunction with a water-cooling heat exchanger under API piping plans 11, 21, 22 or 23.

※ More Customized Sealing Solution. Please feel free to contact us.

Catalog Download

Catalog Download

【Operating Capabilities】

- Temperature: -40 ~ 260°C (-40 ~ 500 °F )

- Pressure: Up to 570 psig (40 kg/cm2G)

-

Surface Speed: Up to 5000 fpm (25 m/s)

- Stationary Ring:Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZ® / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

- Single cartridge configuration complying with the latest API 682 requirements provides greater robustness and ease of installation and removal.

- Balanced design to ensure greater sealing integrity under high-pressure operation.

- Engineered inboard stationary ring to deal with hightemperature and high-pressure conditions, leading to reduced potential for overheating, and longer service life.

- Unique cartridge design features drop-proof springs, speeding installation and maintenance.

- High-efficiency flow guiding ring with 360º circulating holes provides the best cooling, flushing and lubrication effects at the seal faces.

- Monolithic seal faces offer excellent resistance to wear, deformation and thermal stresses.

- Self-aligning compensates for shaft runout up to ±0.5 mm, increasing operational reliability.

- For high-temperature services, API piping plans 22 and 23 are suitable.

- Suitable for API pumps.

- Ideal for high-temperature and high-pressure applications.

- Used in diverse industries, including the refining, petrochemical, pipeline transportation, renewable energy, and power generation industries.