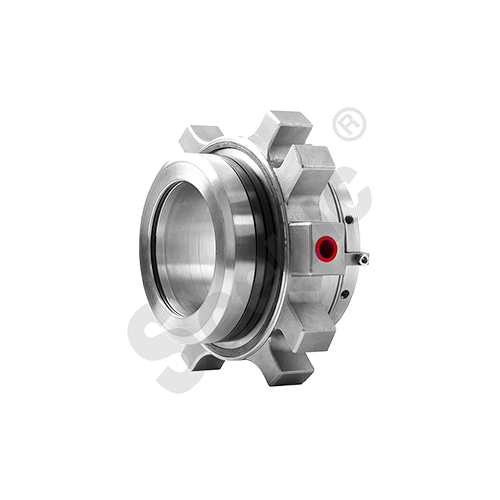

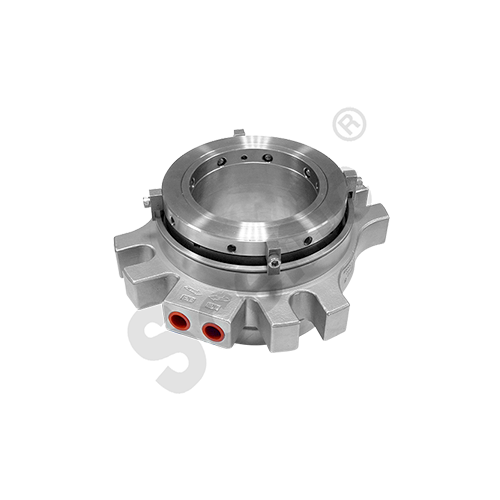

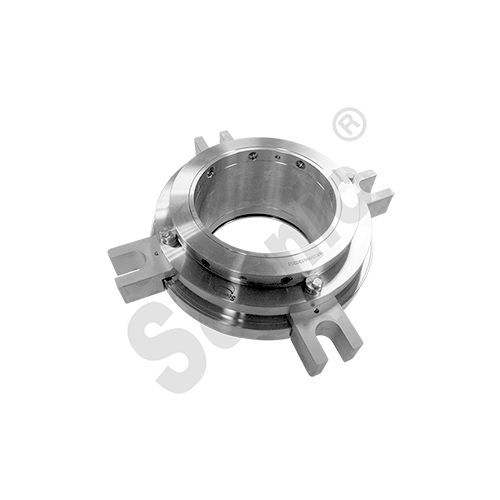

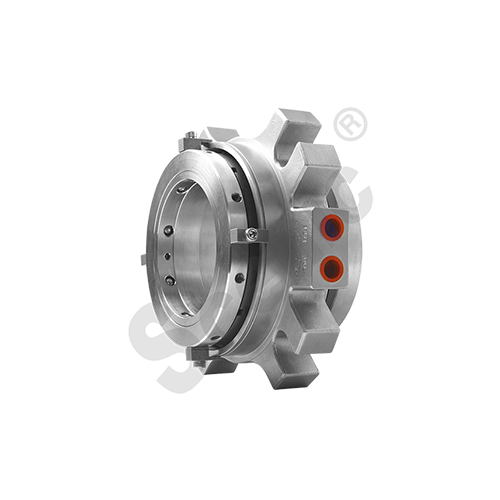

Single Mixer Cartridge Seal MGS1000

PATENTED

☑ For Large Mixers

☑ Dry Running

☑ Low Pressure

☑ Self-alignment

☑ For Large Mixers

☑ Dry Running

☑ Low Pressure

☑ Self-alignment

Model :

MGS1000

【Operating Capabilities】

- Temperature: -40 ~ 150°C (-40 ~ 300 °F )

- Pressure: Up to 43 psig (3 kg/cm2G)

-

Surface Speed: Up to 1000 fpm (5 m/s)

- Stationary Ring:Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZ® / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

- Well suited for high-purity process applications, such as semiconductor manufacture.

- Suited for low-speed rotating equipment under pressurized or vacuum conditions, and with large shaft runout.

- Designed for dry-running with peripheral speed and pressure below 3 m/s and 2 bars, respectively and with no flushing required.

- Static Springs.

- Self-Aligning.

- MGS2000 Compatible.

- Monolithic Mating Face Design.

- Huge mixer/agitator/vessel.

- Rotating equipments in vacuum, low pressure, low temperature and big run-out shaft applications.

- High purity process.

- Pulp and paper, petrochemical, foodstuff processing, chemical processing, and pharmaceutical.

- Scenic® enables to supply special design in accordance with customer requirement.