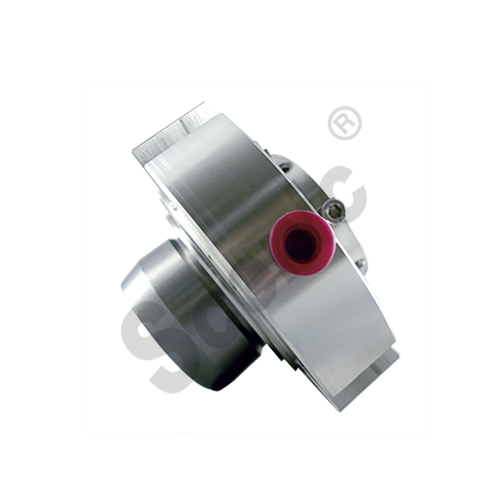

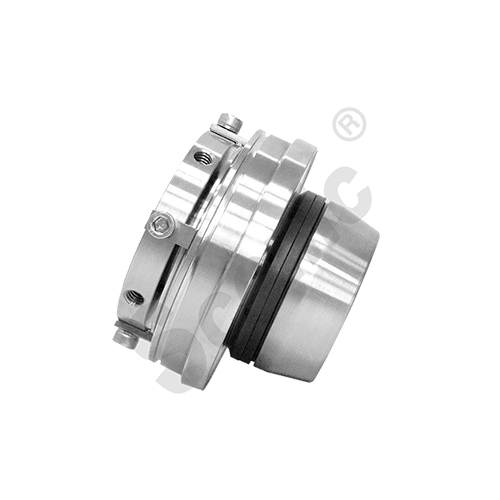

Single Mechanical Seal CarLife79

☑ Single Cartridge Seal

☑ Standard DIN/ANSI

☑ Big bore / Taper bore sizes in inches

☑ Isolated Springs

☑ Pump Seal

☑ Sic/ TC on Wet Process Side

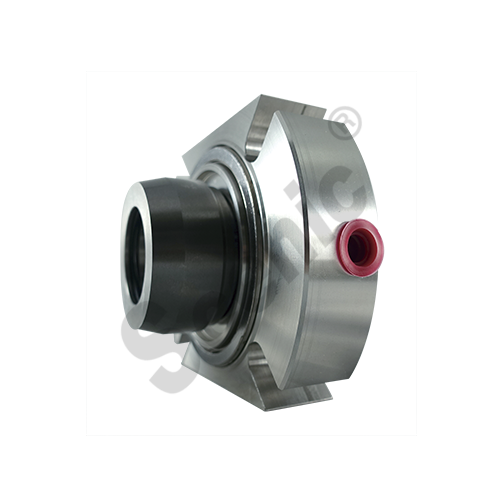

Net Zero Sealing - Process Side Components are Silicon Carbide or Tungsten Carbide

To meet the growing trends of carbon reduction and carbon neutrality, Scenic proudly introduces the all-new CarLife® series single cartridge seal, CarLife®79™ (CL79).

This cutting-edge pump seal revolutionizes traditional corrosion-resistant materials like Hastelloy C (C-276), Hastelloy B, zirconium, titanium by replacing them with high-performance silicon carbide throughout all components in the wet process side. The seamless integration of a unique structural design and silicon carbide material showcases our unwavering commitment to innovation.

Applications for acidic, caustic, corrosive, and abrasive processes

The decision to utilize silicon carbide as the material for the process side stems from its unparalleled attributes, surpassing traditional corrosion-resistant materials in high-temperature resistance, corrosion resistance, erosion resistance, and abrasion resistance. As a result, CarLife®79™ becomes the preferred choice for demanding applications such as high-corrosion pumps and scenarios with high levels of mineral impurities, ensuring extended service life and exceptional performance and durability. Additionally, the production of silicon carbide materials significantly reduces carbon footprint compared to rare metals, minimizing the energy consumption associated with mineral extraction and refining.

As the latest addition to our lineup, CarLife®79™encapsulates Scenic's design prowess and innovative spirit, delivering superior performance and remarkable environmental benefits. Not only does this mechanical seal align with the prevailing materials application trends, but it also exemplifies our unwavering ambition and dedication to making a positive impact.

【Operating Capabilities】

- Temperature: -40 ~ 95℃ (-40 ~203℉)

- Pressure: up to 256 psig (18 kg/cm2G)

-

Surface Speed: up to 2952 fpm (15m/s)

【Standard Materials】

- Stationary Ring: Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Rotary Ring: Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

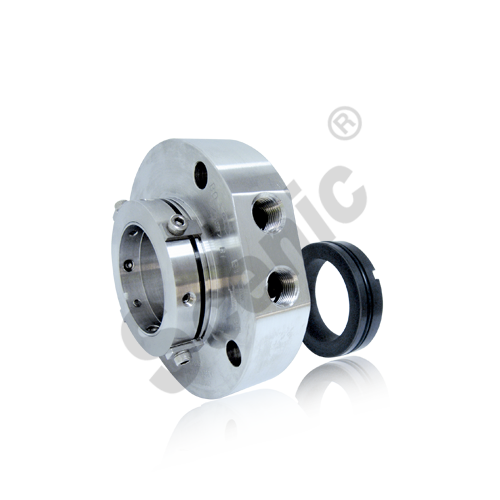

- Elastomeric O-ring: FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZTM / Chemraz® / Kalrez®)

- Gland Gasket: Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

- Single Cartridge Seal Design-Conformed to DIN/ANSI Specification

- Simplefied Structure for Easy Installation, maintenance, trasport, stock & inventory

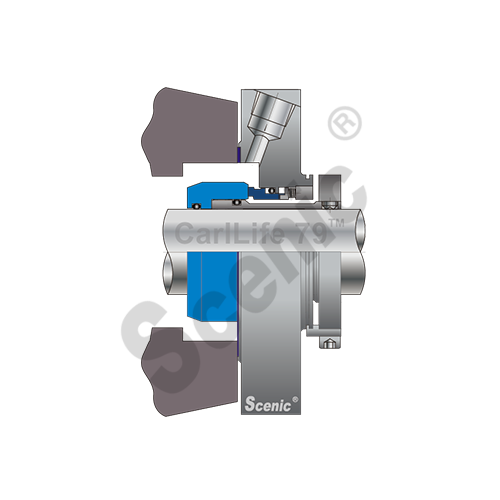

- Self-alignment Capability-Tolerates shaft's greater run-out.

- Balance Design-Computed ultimate area ratio to ensure faces remain closed at any condition; Reduces seal face pressure & saves energy consumption.

- Monolithic Faces-NO distortion or deformation, provide superior wear & corrosion resistance.

- High-intensity drive structure (CP ring): Special key-positioned drive structure, ensuring the stability and durability of the seal ring during start-up and under torque even in high hardness material.

- Carbon reduction material: Replacing precious metal with SIC on the process side components to reduce the carbon footprint generated during production.

- Specially designed for large-scale vertical pumps with large amounts of radial or axial runout.

- Ability to tolerate short intermittent dry-running in batch charging and discharging equipment.

- Suitable for a wide range of rotating equipment, such as water pumps, chemical process pumps, vertical pumps, centrifugal pumps and eccentric screw pumps.

- Ideal for seawater pumps and wastewater treatment pumps for handling dirty and abrasive media containing solids.

- Widely used in the alcohol (e.g. methanol and ethanol), bio-diesel and corn processing industries.

- Capable of handling processes involving acids, alkalis, corrosive fluids and vacuum pressure.

- Suited for a variety of industrial applications, including refining, petrochemical, chemical, food and beverage, pharmaceutical, pipeline transportation, power generation, steel, semiconductor, electronics, biotechnology, water resource, and wastewater treatment.