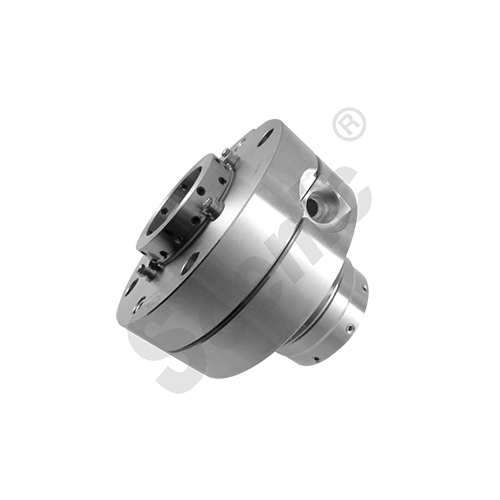

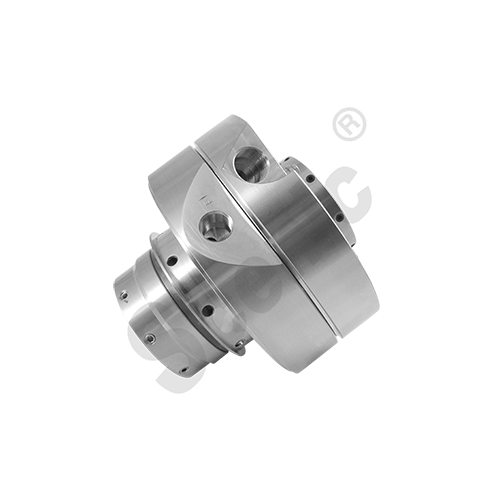

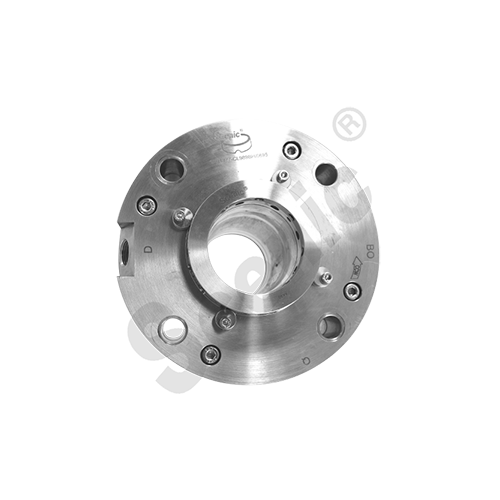

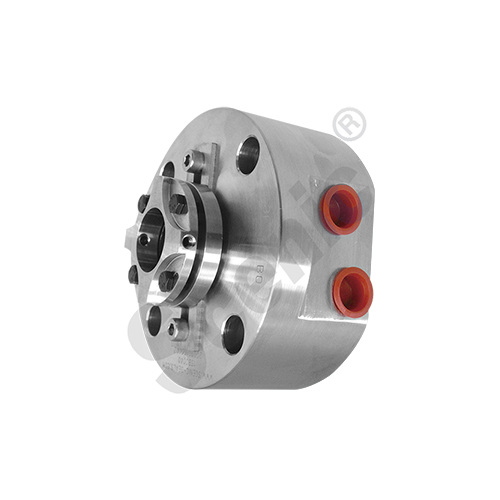

Dual Mechanical Seal APD989

PATENTED

☑ API 682

☑ Dual Cartridge Seal

☑ Specifically developed for high-pressure and mildly abrasive applications

☑ API 682

☑ Dual Cartridge Seal

☑ Specifically developed for high-pressure and mildly abrasive applications

Model :

APD989

The APD®989 seal is designed, manufactured and tested according to API682 4th edition. The sturdy dual cartridge construction of this seal provides high-pressure capability and good resistance to small abrasives, and hence is well suited to handle high-pressure and easy-to-vaporize media.

With balanced design for both pressure directions, the APD®989 seal operates well with a barrier/buffer fluid pressurized or unpressurized, depending on the application; the pressurized mode is equivalent to API 682 piping plan 53/54 while the unpressurized mode equivalent to plan 52. When used in conjunction with an SP-3GL or 5GL seal reservoir, the seal can eliminate or minimize VOC emissions to comply with the environmental emission regulations, leading to improved air quality during production processes.

With balanced design for both pressure directions, the APD®989 seal operates well with a barrier/buffer fluid pressurized or unpressurized, depending on the application; the pressurized mode is equivalent to API 682 piping plan 53/54 while the unpressurized mode equivalent to plan 52. When used in conjunction with an SP-3GL or 5GL seal reservoir, the seal can eliminate or minimize VOC emissions to comply with the environmental emission regulations, leading to improved air quality during production processes.

※ More Customized Sealing Solution. Please feel free to contact us.

Catalog Download

Catalog Download

【Operating Capabilities】

- Temperature: -40 ~ 310°C (-40 ~ 583°F )

- Pressure: Up to 558 psig (38 kg/cm2G)

-

Surface Speed: Up to 5000 fpm (25 m/s)

- Stationary Ring:Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZ® / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

- Produced with rugged and robust dual cartridge construction, the seal is operator-friendly and complies with the latest API 682 3CW-FB standard.

- Featuring advanced transmission mechanism, this seal has selfaligning and anti-vibration capabilities, allowing for shaft runout up to ±0.5mm, and has proven to deliver excellent performance when handling high-pressure and easy-to-vaporize media.

- The inner springs are non-rotating and isolated from the process medium during operation, therefore free from damage caused by crystallizing or corrosive medium and from flow shear and drag due to rotating springs under high pressures. In addition, since the springs are drop-proof, the seal can readily be installed or replaced.

- Each APD 989 sealing ring is made in one solid piece and meets API materials requirements. In particular, the sealing faces with optional materials are resistant to high pressures and short-period dry running, greatly increasing the seal's strength and life cycle.

- With the assistance of the high-efficiency pumping ring, coupled with the venting outlet hole in the gland ring, in circulating the cooling fluid, this design provides the best possible cooling fluid supply to carry away seal-generated heat and thus the best cooling effect at the sealing faces.

- Ideal for API 682 pumps and equipment for use in the oil and petrochemical processing industries.

- Suitable for DIN/ANSI pumps and equipment operating at high pressures.

- APD 989 series seal is available in standard and custom configurations to suit each customer's specific equipment.