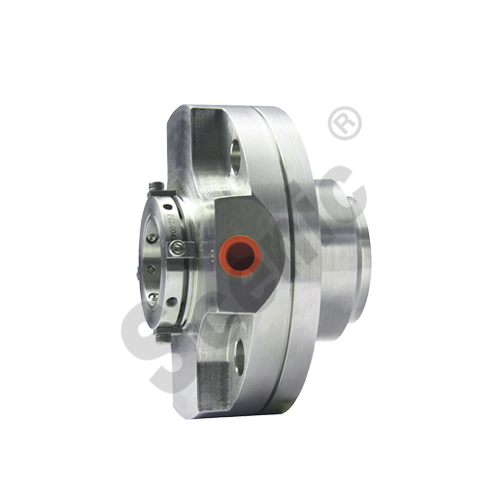

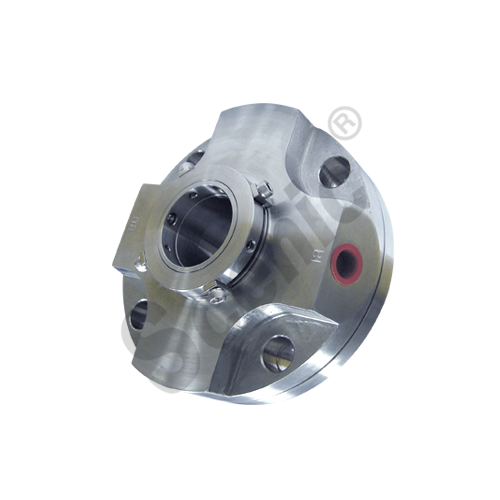

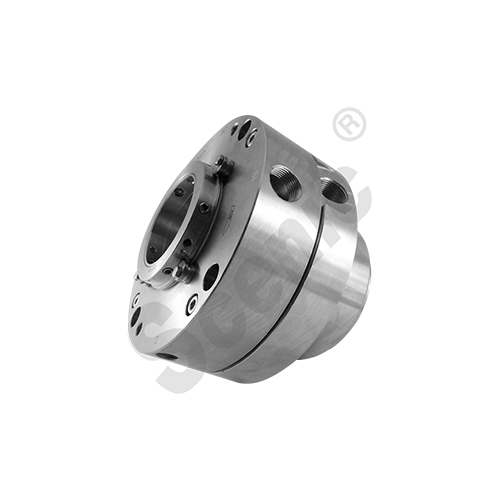

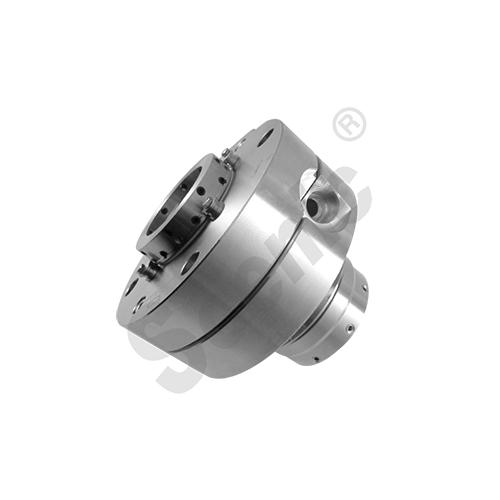

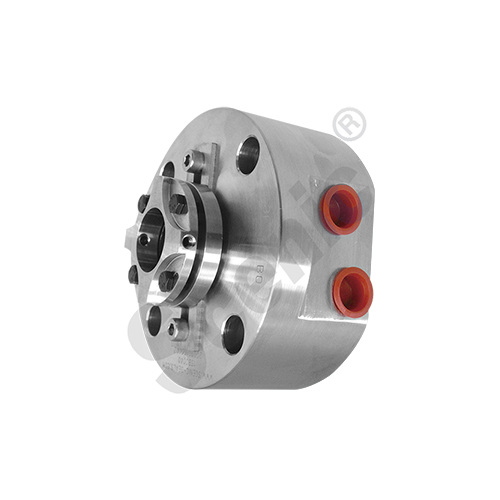

Dual Mechanical Seal APD302 / APD302SD

PATENTED

☑ Dual Cartridge Seal

☑ API 682 Standard

☑ High Temperature

☑ High Pressure

☑ Highly Abrasive

☑ Very Viscous Fluids

☑ Light solids

☑ Isolated Springs

☑ Dual Cartridge Seal

☑ API 682 Standard

☑ High Temperature

☑ High Pressure

☑ Highly Abrasive

☑ Very Viscous Fluids

☑ Light solids

☑ Isolated Springs

Model :

APD302/302SD

The APD®302 and 302SD seals are designed, manufactured and tested according to API 4th edition.

While APD®302 is the prototype, both seals have rugged construction and superior clogging resistance. Designed for harsh operating conditions, they are especially suited for high-pressure and high-temperature processes with crystallizing, highly abrasive or viscous media.

- APD®302:Design for medium abrasion, high abrasion, and viscosity services.

- APD®302SD:Customized design for high abrasion or viscosity services.

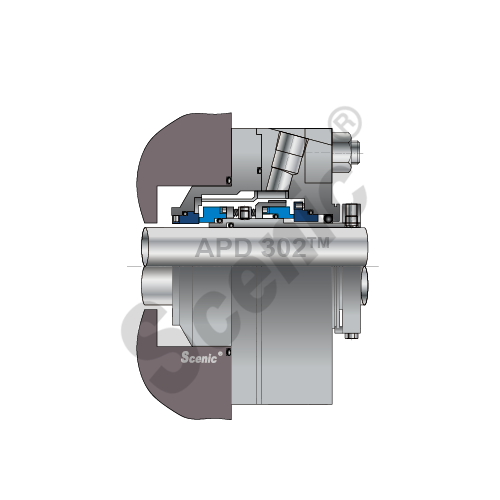

【Operating Capabilities】

【Standard Materials】

※ Custom designs are available to cover the specific needs of customers. Please feel free to contact us.

- Temperature:-40 ~ 230℃ (-40 ~ 446 ℉ )

- Pressure: up to 430 psig (30 kg/cm2G)

- Surface Speed: Up to 5000 fpm (25 m/s)

【Standard Materials】

- Stationary Ring:Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide / Carbon Graphite

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZ® / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / Spiral-Wound

- Springs:316 SS / Alloy C-276 / Inconel®

※ Custom designs are available to cover the specific needs of customers. Please feel free to contact us.

- Designed for heavy industry pumps pumping very viscous media, such as asphalt or pitch transfer pumps under high temperature towers, large heavy oil transfer pumps and refining process pumps.

- Prevent hazardous emissions of acidic, caustic, corrosive, volatile and toxic media.

- Ideal for high viscosity applications, such as emulsions, latex and rubber.

- Reliable sealing for high temperature, high or varying pressure processes.

- Engineered to cope with process fluids prone to crystallize, or with a high percentage of abrasive solids or powder.

- Withstand dry running involved with frequent starts and stops.

- Used for dry-running applications in specialty equipment, such as air transportation blowers.

- Ability to tolerate short intermittent dry-running in batch charging and discharging equipment.

- Widely used in the refining, petrochemical, rubber, chemical, food and beverage, pharmaceutical, pipeline transportation, renewable energy, and power generation industries.