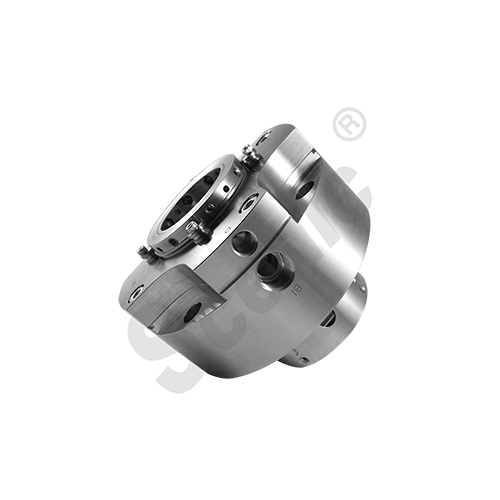

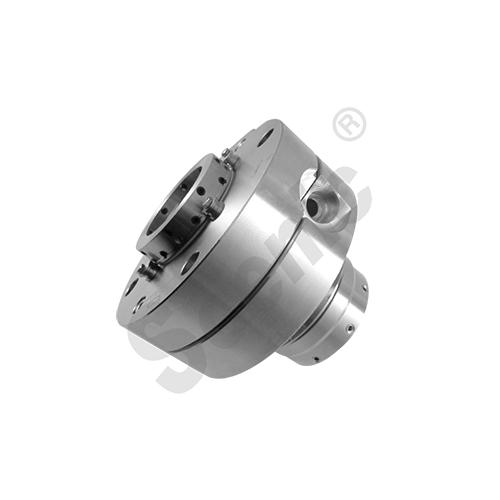

Dual Cartridge Seal APD355

PATENTED

☑ API 682

☑ Tandem cartridge seals for refining and petrochemical processes

☑ Dual Cartridge Seal

☑ API Big-Bore Standard

☑ API 682

☑ Tandem cartridge seals for refining and petrochemical processes

☑ Dual Cartridge Seal

☑ API Big-Bore Standard

Model :

APD355

The APD®355 seal is designed and manufactured according to the revised API 682 4th Edition. Specially engineered to cover the needs of the refining and petrochemical industries, the APD®355 is especially suited for high-temperature and high-pressure applications.

Fitting API enlarged bore rotating equipment, this seal is primarily applied in refining, petrochemical, pipeline transportation and renewable energy industries. When used in conjunction with an SP-3/5GL seal reservoir, the seal can eliminate or minimize VOC emissions.

Fitting API enlarged bore rotating equipment, this seal is primarily applied in refining, petrochemical, pipeline transportation and renewable energy industries. When used in conjunction with an SP-3/5GL seal reservoir, the seal can eliminate or minimize VOC emissions.

※ More Customized Sealing Solution. Please feel free to contact us.

Catalog Download

Catalog Download

【Operating Capabilities】

- Temperature: -40 ~ 260°C (-40 ~ 500 °F )

- Pressure: Up to 570 psig (40 kg/cm2G)

-

Surface Speed: Up to 5000 fpm (25 m/s)

- Stationary Ring:Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

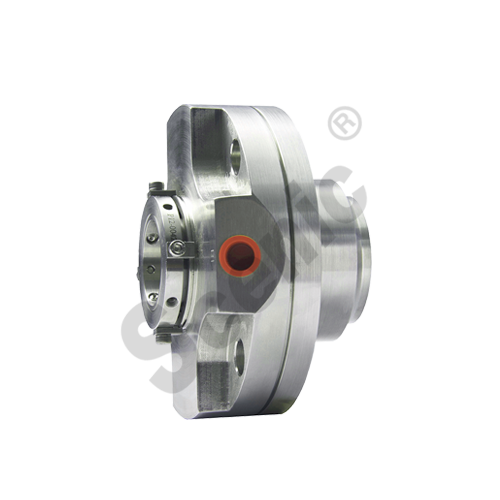

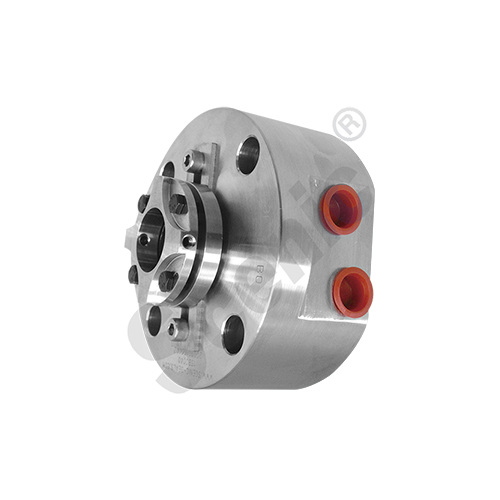

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZ® / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

- Balanced seal designed to handle higher pressures and generate less heat.

- The inboard stationary ring maintains consistent strength under high-temperature, high-pressure conditions, and has reduced potential for overheating, leading to longer service life.

- Monolithic sealing faces according to the API 682 standard offer excellent wear and chemical resistance.

- High-efficiency pumping ring, coupled with the venting outlet hole, provides the best cooling, flushing and lubrication effects at the sealing faces by circulating the barrier or buffer fluid to carry away seal-generated heat, resulting in extended seal life and MTBF (Mean Time Between Failures).

- As a reversible balanced seal, the inboard seal is designed to seal equally well with pressure from either direction.

- Self-aligning compensates for shaft runout up to ±0.5 mm, increasing operational reliability.

- Recommended API piping plans 52, 53 and 54 with a choice of pressurized barrier fluid or unpressurized buffer fluid, depending on the application requirements.

- For high temperature services, API piping plans 22 and 23 are suitable.

- A patented impact absorbing washer is utilized to ensure sparkfree operation, greatly reducing the risk of on-site catastrophic fire.

- Ideal for high-temperature, high-pressure processes.

- Suited for API process pumps and chemical liquid transfer pumps.

- Designed for sealing hazardous emissions of acidic, caustic, corrosive and toxic media, and containing light hydrocarbons, including VOCs.

- Used in diverse industries, including the refining, petrochemical, pipeline transportation, renewable energy, and electric power industries.