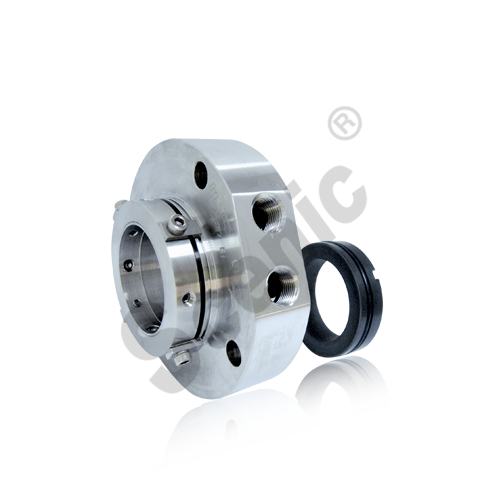

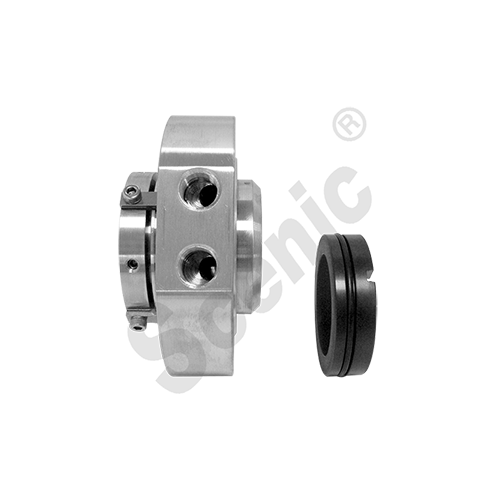

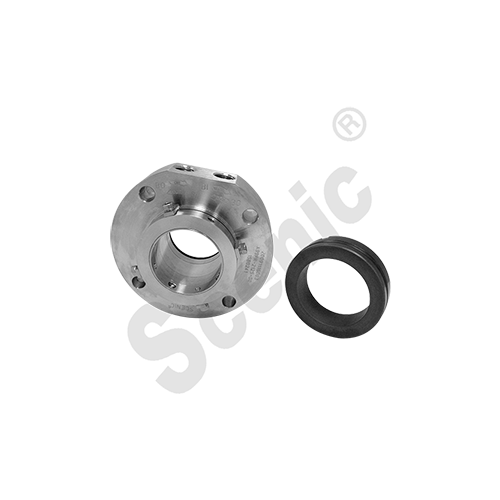

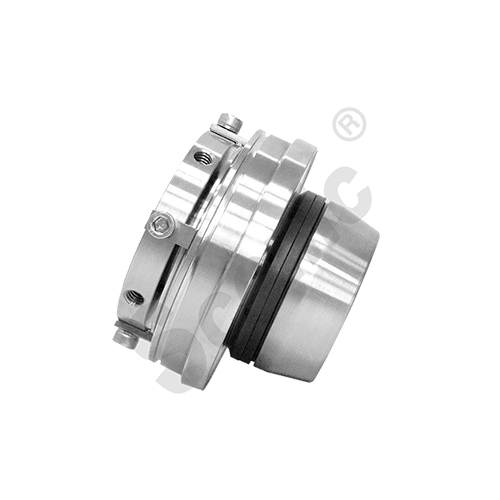

Single Mechanical Seal CarLife99PR

PATENTED

☑ Single Cartridge Seal

☑ DIN/ANSI

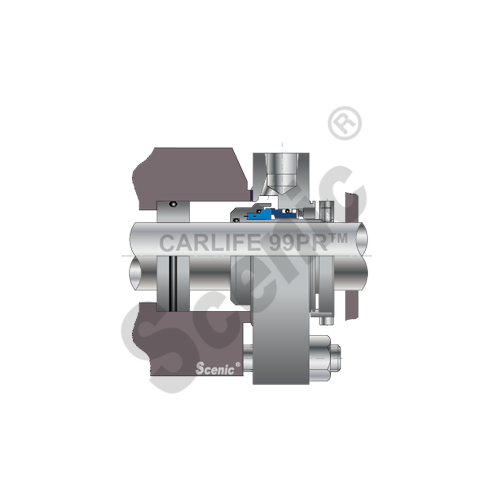

☑ API PLAN 23

☑ Isolated Springs

☑ Boiler Feed Water Pump (BFW Pump)

☑ High Temp.

☑ Single Cartridge Seal

☑ DIN/ANSI

☑ API PLAN 23

☑ Isolated Springs

☑ Boiler Feed Water Pump (BFW Pump)

☑ High Temp.

Model :

CL99PR

CarLife® 99PR is a high-flow circulation pump seal designed specifically for high-temperature processes exceeding 80℃. When equipped with a dedicated heat exchanger (WCHE) and a throat bushing on the process side, and utilizing the API Piping Plan23, it provides superior heat dissipation.

CarLife® 99PR is the ideal sealing solution for boiler feed water pumps (BFW Pump) and is commonly employed in high-temperature or volatile processes such as hot water, thermal oil, and chemical solvents, including applications in power plants.

※ More Customized Sealing Solution. Please feel free to contact us.

Catalog Download

Catalog Download

【Operating Capabilities】

- Temperature: -40 ~ 230°C (-40 ~ 446 °F )

- Pressure: Up to 300 psig (21 kg/cm2G)

-

Surface Speed: Up to 5000 fpm (25 m/s)

【Standard Materials】

- Stationary Ring:Carbon Graphite / Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZTM / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / O-Ring

- Springs:316 SS / Alloy C-276 / Inconel®

- Recommended Piping Plans : Plan 23

- The patented cartridge design features innovative drop-proof springs, thereby speeding installation and maintenance.

- Our jumbo coil springs have better wear resistance than many other brands.

- Balanced design for both pressure directions, promoting a higher level of sealing stability.

- Flexible piping plans with a barrier/buffer fluid pressurized or unpressurized, depending on the application.

- Robust construction with large runout capability.

- Self-aligning compensates for shaft runout up to ±0.8 mm, increasing operational reliability.

- Micro-polished outer surfaces of O-rings for anti-stick mounting.

- Natural circulation heat exchanging design delivers bidirectional cooling flows at high flow rates, greatly extending MTBF (Mean Time Between Failures) because ofless heat.

- Monolithic sealing faces with precise dimensions and excellent resistance to wear.

- Low emissions design effectively contains VOC emissions.

- Interchangeable inboard and outboard sealing faces.

- Maximum interchangeability of parts among the CarLife® family.

- Ability to tolerate short intermittent dry running in batch charging and discharging equipment.

- Prevent hazardous emissions of acidic, caustic, corrosive, volatile and toxic media.

- Withstand dry running involved with frequent starts and stops.

- Suitable for a wide range of rotating equipment, such as chemical process pumps, vertical pumps, centrifugal pumps, vacuum pumps and eccentric screw pumps.

- Widely used in the alcohol (e.g. methanol and ethanol), bio-diesel and corn processing industries.

- Suited for a variety of industrial applications, including refining, petrochemical, chemical, food and beverage, pharmaceutical, pipeline transportation, power generation, steel, semiconductor, electronics, biotechnology, water resource, and wastewater treatment.