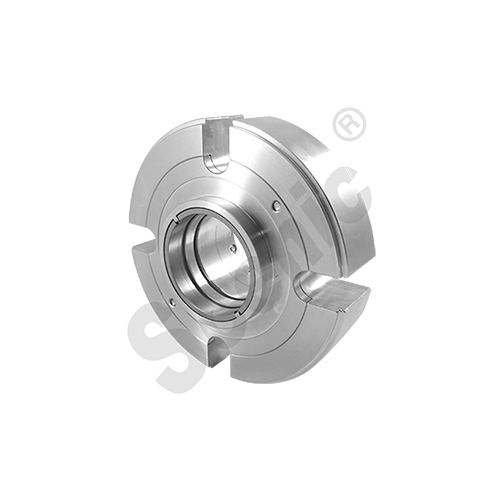

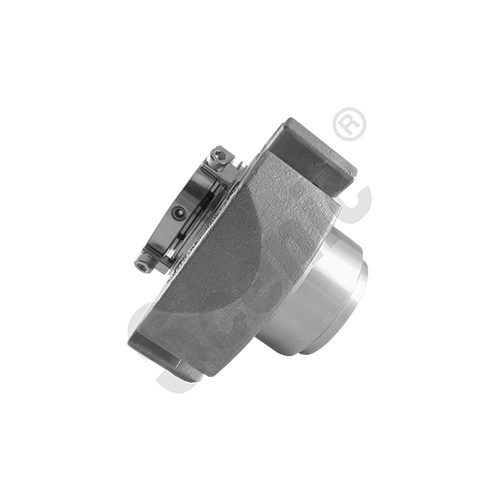

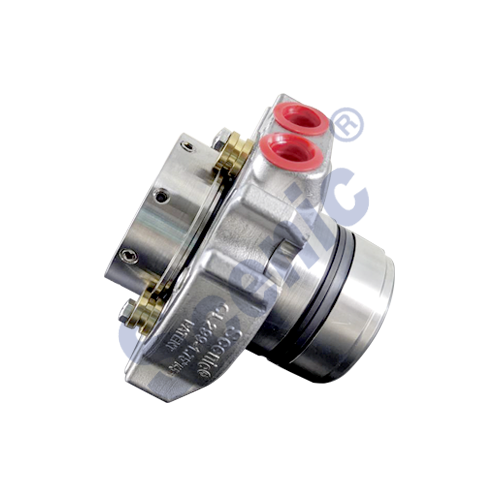

Slurry Dual Mechanical Seal APD302T / 302TSD

PATENTED

☑ Dual Cartridge Seal

☑ DIN/ANSI Big Bore / Tapered Bore

☑ High Temperature

☑ High Pressure

☑ Highly Abrasive

☑ Very Viscous Fluids

☑ Light solids

☑ Isolated Springs

☑ Dual Cartridge Seal

☑ DIN/ANSI Big Bore / Tapered Bore

☑ High Temperature

☑ High Pressure

☑ Highly Abrasive

☑ Very Viscous Fluids

☑ Light solids

☑ Isolated Springs

Model :

APD302T / 302TSD

The APD302T and 302TSD seals are designed, manufactured and tested according to API Standard 4th edition. While APD302T is the prototype, both seals have rugged construction and superior clogging resistance. Designed for harsh operating conditions, they are especially suited for high-pressure and high-temperature processes with crystallizing, highly abrasive or viscous media.

(1)APD302T:Standard design for medium / high abrasion or viscosity services.

(2)APD302TSD:Custom design for high abrasion or viscosity services.

(1)APD302T:Standard design for medium / high abrasion or viscosity services.

(2)APD302TSD:Custom design for high abrasion or viscosity services.

※ More Customized Sealing Solution. Please feel free to contact us.

Catalog Download

Catalog Download

【Operating Capabilities】

- Temperature: -40 ~ 310°C (-40 ~ 583 °F )

- Pressure: Up to 427 psig (30 kg/cm2G)

- Surface Speed: Up to 5000 fpm (25 m/s)

【Standard Materials】

- Stationary Ring:Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide / Carbon Graphite

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZTM / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / Spiral-Wound

- Springs:316 SS / Alloy C-276 / Inconel®

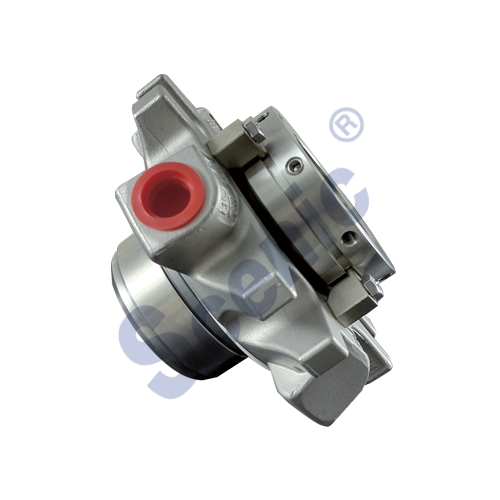

- Designed for heavy industry pumps pumping very viscous media, such as asphalt or pitch transfer pumps under high temperature towers, large heavy oil transfer pumps and refining process pumps.

- Prevent hazardous emissions of acidic, caustic, corrosive, volatile and toxic media.

- Ideal for high viscosity applications, such as emulsions, latex and rubber.

- Reliable sealing for high temperature, high or varying pressure processes.

- Engineered to cope with process fluids prone to crystallize, or with a high percentage of abrasive solids or powder.

- Withstand dry running involved with frequent starts and stops.

- Used for dry-running applications in specialty equipment, such as air transportation blowers.

- Ability to tolerate short intermittent dry-running in batch charging and discharging equipment.

- Widely used in the refining, petrochemical, rubber, chemical, food and beverage, pharmaceutical, pipeline transportation, renewable energy, and power generation industries.