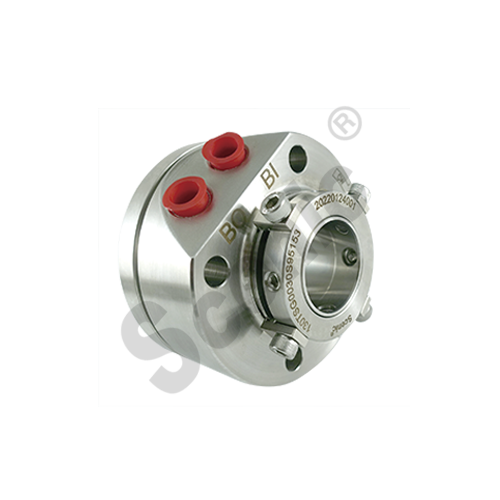

Dual Mechanical Seal APD302TSG

PATENTED

☑ Dual Cartridge Seal

☑ Standard DIN/ANSI

☑ High Temperature

☑ High Pressure

☑ Highly Abrasive

☑ Very Viscous Fluids

☑ Light solids

☑ Isolated Springs

☑ Dual Cartridge Seal

☑ Standard DIN/ANSI

☑ High Temperature

☑ High Pressure

☑ Highly Abrasive

☑ Very Viscous Fluids

☑ Light solids

☑ Isolated Springs

Model :

APD302TSG

【Operating Capabilities】

【Standard Materials】

- Temperature: -40 ~ 310°C (-40 ~ 583 °F )

- Pressure: Up to 427 psig (30 kg/cm2G)

- Surface Speed: Up to 5000 fpm (25 m/s)

【Standard Materials】

- Stationary Ring:Silicon Carbide / Tungsten Carbide

- Rotary Ring:Silicon Carbide / Tungsten Carbide / Carbon Graphite

- Metal Parts:316 SS / 304 SS / 316L SS / 316Ti SS / Duplex Stainless / Alloy C-276 / Titanium / Monel®

- Elastomeric O-rings:FKM / AFLAS / NBR / EPDM / TV / FFKM (SceniRAZTM / Chemraz® / Kalrez®)

- Gland Gasket:Glass-Filled PTFE / Non- Asbestos / Spiral-Wound

- Springs:316 SS / Alloy C-276 / Inconel®

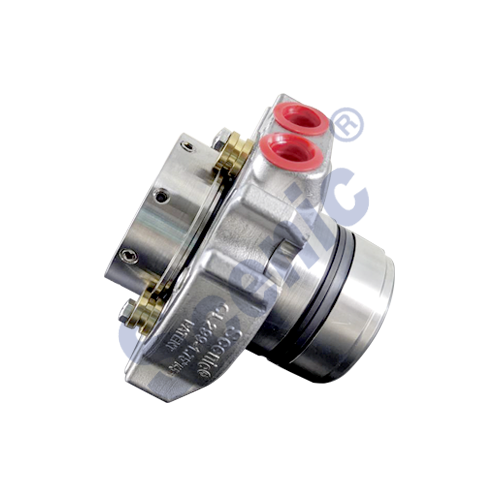

- The patented cartridge design features innovative dropproof springs, thereby speeding installation and maintenance.

- High duty transmission construction ensures consistent performance.

- The springs are divorced from the process media, and thus free from cracking and clogging problems due to stress corrosion and solids, respectively.

- Our jumbo coil springs have better wear resistance than many other brands.

- Designed to eliminate the risk of clogging caused by fluids with medium solids or medium viscosities.

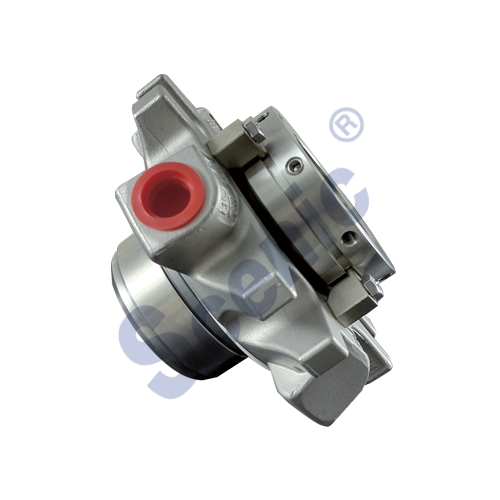

- Balanced design for both pressure directions.

- Self-aligning compensates for shaft runout up to ±0.5 mm, increasing operational reliability.

- Multi-stage heat exchanging design, including a cylindrical cooling jacket, delivers bidirectional cooling flows at high flow rates, greatly extending MTBF (Mean Time Between Failures) because of less heat.

- Capable of near-zero VOC emissions by using a barrier fluid maintained at a proper pressure.

- Flexible piping plans with a barrier/buffer fluid pressurized or unpressurized, depending on the application.

- Monolithic sealing faces with precise dimensions and excellent resistance to wear.

- Designed for heavy industry pumps pumping very viscous media, such as asphalt or pitch transfer pumps under high temperature towers, large heavy oil transfer pumps and refining process pumps.

- Prevent hazardous emissions of acidic, caustic, corrosive, volatile and toxic media.

- Ideal for high viscosity applications, such as emulsions, latex and rubber.

- Reliable sealing for high temperature, high or varying pressure processes.

- Engineered to cope with process fluids prone to crystallize, or with a high percentage of abrasive solids or powder.

- Withstand dry running involved with frequent starts and stops.

- Used for dry-running applications in specialty equipment, such as air transportation blowers.

- Ability to tolerate short intermittent dry-running in batch charging and discharging equipment.

- Widely used in the refining, petrochemical, rubber, chemical, food and beverage, pharmaceutical, pipeline transportation, renewable energy, and power generation industries.

- The patented cartridge design features innovative dropproof springs, thereby speeding installation and maintenance.